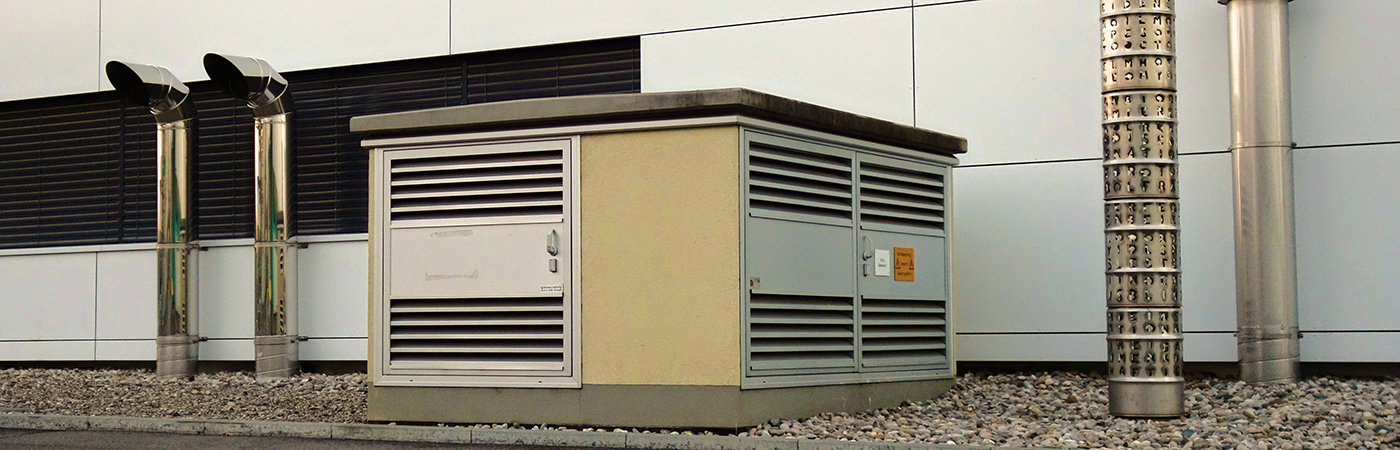

Compact transformer stations in tested quality

Factory manufactured compact stations tested according to current state-of-the-art technology!

The UK transformer station, can be operated from the outside, is disassembled at the Villmergen factory and installed on-site in one day.

The UK model can be designed compliant with the type test standard SN EN 62271-202 for prefabricated stations and is available in a wide variety of configurations. Despite its rather compact dimensions, the variants cover many client requirements.

The UK building station

The UK model is made by Betonbau GmbH und Co. KG, Germany. It is a prefabricated building station, and the concrete cabin can be operated from the outside.

Within the type test standard SN EN 62271-202, this station type for prefabricated stations is characterised by an extremely wide variety of configurations. It represents an alternative to the conventional FORA compact station, especially if the desired system combination in the FORA design cannot be offered as type-tested.

The entire electrical installation of the UK is conducted in our factory in Villmergen. Transportation to the construction site and installation on-site is also carried out by BBC Cellpack Power Systems. The work is completed the same day.

The structure is manufactured in one piece and without joints. Its height above the ground can be kept to a minimum, depending on the design. The transformer capacity can be up to 1,250 kVA, depending on the size of the building.

As for all station types of our product range, multiple surface and façade variants are available. Synthetic resin plaster is our standard coating. The colour is your choice.

Product features

Installation

free-standing (standard), slope installation, installation on in-situ concrete, other options

Operating temperature

outdoors -40 °C to 35 °C / indoors -5 °C to 45 °C

Type testing

SN EN 62271-202 incl. Internal Arc Classification IAC AB 20 kA (1 s) with all MV switchgear types

Standard façade surface

Synthetic resin plaster, the colour is your choice

Foundation: Bitumen protective coating, black, Ilack C

Optional façade surfaces

Anti-graffiti protection, various coverings

Concrete quality

• Reinforced concrete, C35/45, XC4, XA1, XF1 compliant with SN EN 206-1

• Fire resistance class: REI 60

• proven oil tightness compliant with VSE 2.19 d

Interior paint

entire interior painted with white water-based dispersion

Operating, transformer, and service door

Aluminium, colourless anodised or painted, with ventilation louvers

False floor

Consisting of an aluminium frame to which pressure-proof, phenolic resin-coated plywood panels are bolted. The surface of these panels is slip-resistant, and moisture resistant

Oil collecting sump

as an option, this sump may be made of GFRP, consist of a steel tub, or an oil-tight collecting area integrated into the foundation; optional additional oil-tight coating for protection zone S3 compliant with VSE 2.19 d is available

Lifting equipment

four lifting points are recessed on the foundation's exterior

Cable entries

Entry system, quantity, size and position according to customer specifications

Construction power entry

Ø 90 mm, with aluminium cover (position according to customer specifications)

Earthing system

consisting of an all-round main earth line made of Cu Ø 8 or Ø 10 mm and earthing busbar

Earth cable feedthroughs

two feedthroughs are located on the diagonally opposite walls of the cable duct and are connected to the concrete reinforcement bars, optional isolated feedthroughs and earthing points on one side

Station accessories

wide range of options and equipment available